Superior Materials for Military & Commercial Applications

At ASCM, we manufacture three products that can be customized to your specifications:

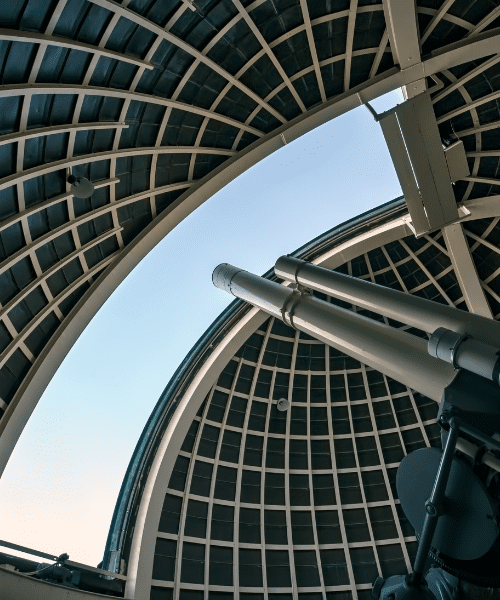

CVC SiC® – This high-purity, ultra-high temperature material is ideal for use in telescopes, optical applications and extreme environments. It is available in thicknesses ranging from 1mm to 75mm in a variety of shapes and sizes. Our unmatched combination of quality and flexibility make us your supplier of choice for optical grade, robust SiC.

Advantages of CVC SiC®

- Purity greater than 99.99% (less than 5 ppm total)

- Rapid growth rate (>5x CVD SiC)

- Near net shaping (conformal deposition)

- Diameters – up to 1500 mm

- Inherently low stress

- Low or high resistivity

- High stiffness with low CTE

- Dimensional stability

- Inherently radiation hard

- Associated rad hard and space hard coatings

- Directly polishable

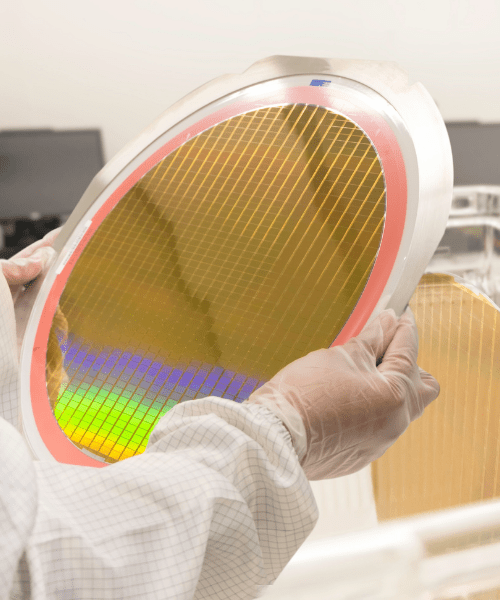

OMNI SiCTM (CVD SiC) – With a purity level that sets it apart, our OMNI SiC™ (CVD SiC) is ideal for use in Semiconductor manufacturing and silicon wafer processing. This material has excellent chemical resistance, outstanding machinability, high thermal conductivity, and long wear life. OMNI SiC™ is available in thicknesses ranging from less than 1mm to 15mm.

Advantages of OMNI SiCTM

- Purity greater than 99.99% (less than 5 ppm total)

- Low or high resistivity

- Excellent chemical resistance

- Diameters – 500 mm

- Outstanding machinability

- High thermal conductivity

- Superior corrosion resistance

- Long wear life

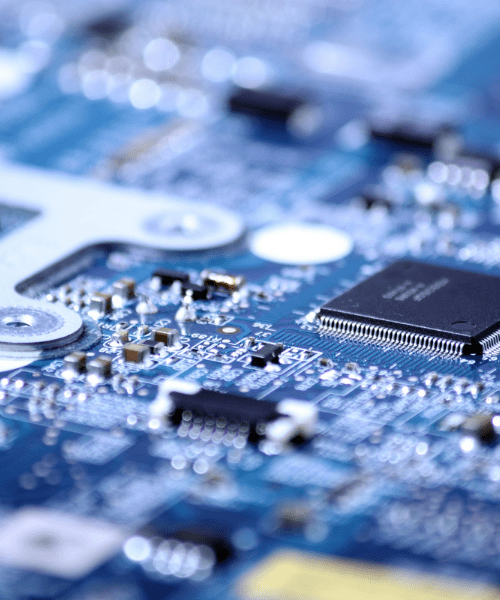

HoneySiC® – This lightweight wafer technology is exceptionally strong, making it ideal for use in microchips and complementary structures. We provide HoneySiC® in thicknesses ranging from less than 1mm to hundreds of millimeters with purity on par with our CVC® and Omni SiC™.

Learn how we can maximize material properties to your advantage.